News

- Industry news

Industry news

Mould science knowledge - those things that export mould

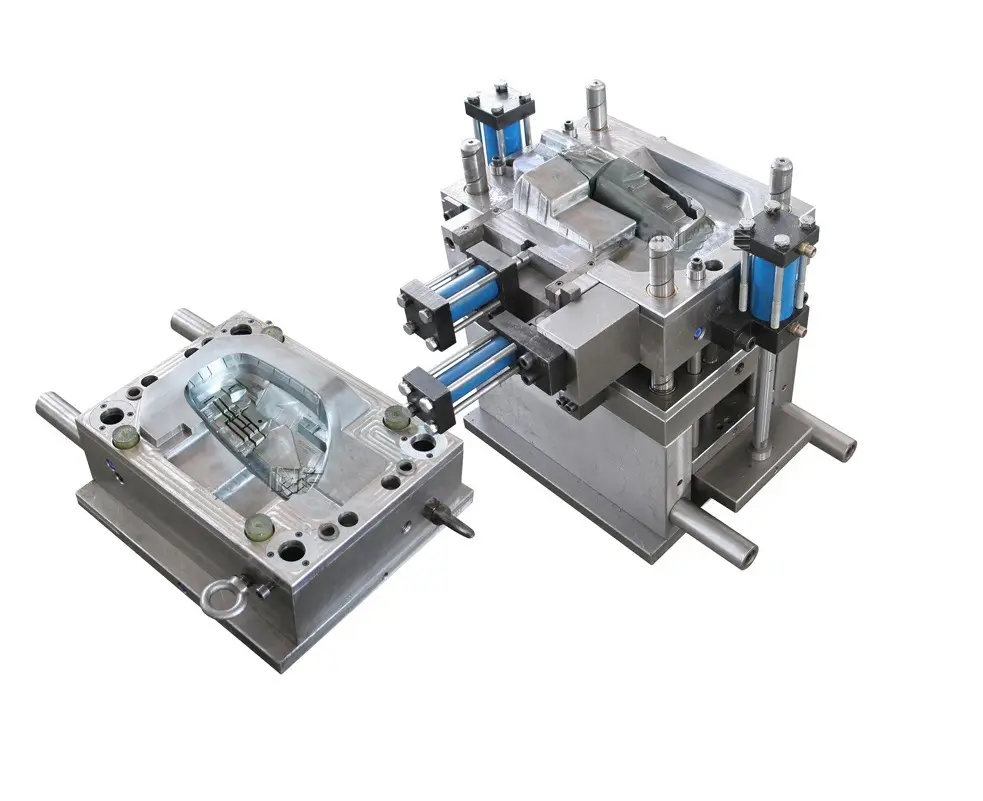

What is export mold?

Export refers to the sale of goods produced or processed in the country to foreign markets. Compared with the export of ordinary goods, the export mold is very different, although there are many countries in China's mold manufacturing exports, such as the Middle East, North America and Europe, near to South Korea, Japan, Southeast Asia and other countries, are the destinations of China's foreign export mold, but the mold industry refers to the mold export to North America, Europe and the United States and South Korea and other countries and regions of the mold.

Three standards for export mold standards

1. Design standards

Design standards are the standards and requirements that need to be followed in the design process of the die

① Size standard

The size of the export mold should conform to international standards or customer requirements.

② Material standard

The materials of the export mold need to meet international standards or requirements provided by customers. Commonly used materials are P20, 718, H13 and so on.

③ Process standard

The processing process of export molds needs to meet international standards or requirements provided by customers. For example, heat treatment of molds, surface treatment, etc.

2. Manufacturing standards

Manufacturing standards are the standards and requirements that need to be followed in the manufacturing process of the mouth mold

① Process requirements

The manufacturing process of export molds needs to meet international standards or requirements provided by customers. Including mold processing accuracy, surface finish and so on.

② Detection requirements

The manufacturing process of the export mold requires various inspections and tests to ensure the quality of the mold. Testing requirements include size testing, hardness testing, material testing, etc.

③ Delivery requirements

The delivery time and method of export molds need to meet international standards or requirements provided by customers. Include delivery date, mode of transportation, packing requirements, etc

3. Quality standards

Quality standard refers to the quality requirements of the mouth mold.

① Appearance quality: The appearance of the export mold should be complete and smooth, without obvious scratches, bubbles, cracks and other defects.

2 Dimensional accuracy: the dimensional accuracy of the export mold should meet the design requirements, and the size deviation should be within the allowable range.

③ Performance indicators: The performance indicators of the export mold should meet international standards or requirements provided by customers. For example, the hardness of the mold, tensile strength, etc.

In summary, the standards for export molds cover many aspects such as design, manufacturing and quality. Only by meeting these standards can export products that meet customer requirements be produced. And our Guangzhou Best Rubber & Plastic Co., Ltd. has more than 20 years of export mold processing business, strong strength, worth your choice!

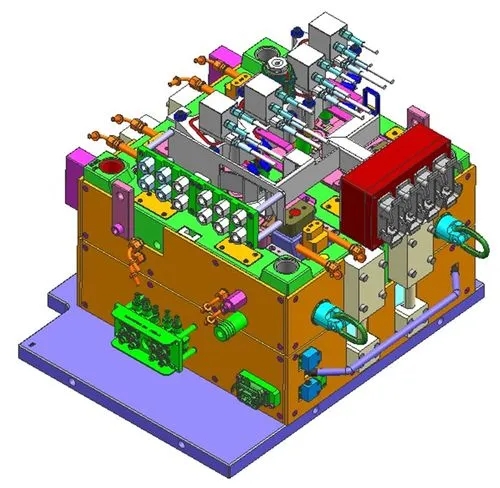

Design requirements for exit die slider mechanism

1. Design of slider insert

When the rear die slider is protruding from the front die, it must be inserted at a 3 degree Angle with the front die kernel, and the bottom should also be designed at a 3 degree Angle with the rear die kernel.

2. Design of shovel

For the sliding block with appearance requirements and the area of the sliding block is relatively large, the shovel must be designed to backhoe, and the contact surface with the slider seat must be designed to wear the block.

3. Pressure plate design requirements

The platen is divided into three types, flat guide, flat L-guide and sunken L-guide.

4. Limit device design requirements

1) Limit blocks must be added to all row positions. It is forbidden to use screw cup head as limit blocks. When the limit blocks are not locked on the side of the template, they should be sunk into the template 5mm for positioning to prevent the screws of the limit blocks from being forced.

2) The dayside position should be limited by the way of spring + position clamp, and ensure that the clamping force of the position clamp is > the weight of the position, and the other position can be used with the position clamp or position buckle. Line clips are generally DME and STRACK line clips, and the assembly gap must refer to the standard when using line clips.

5. Oil tank design requirements

When the customer has a requirement to draw the oil tank on the 3D design, it will only be painted, otherwise it will only be used as a guide for the workshop to process the oil tank.

Production standards for export molds

1, mold life

The minimum life of the export mold needs 1 million times, and the general range is 3 million times -5 million times.

2. Steel

Due to the high requirements on the service life of the mold, all the main steel materials need to be imported and purchased from the original factory, and need to be heat treated. Generally imported steel materials have high strength and corrosion resistance and polishing properties.

3. Accessories

HASCO (metric standard) is mainly used in Europe, DME (imperial standard) is mainly used in the Americas.

4, in order to save rubber material, control costs, most of the export mold will use hot runner into the pouring.

5, HASCO/INCOE/MASTER/GUTHER Synventive/HUSKY/HRS/etc, specific general customers will have specific requirements. Other basic standards: the distance between the top pin hole and the edge of the water transport hole, as well as the edge of the inclined top hole and the insert hole must be guaranteed at least 6 mm, and sometimes it can not reach 3MM or less as the domestic mold. All unsealed and sealed positions of the mold shall be chamfered and shall not have favorable edges (taking into account worker safety). ; In the mold design or modification of the mold, if there is any change, it must be approved by the customer, including adding inserts, replacing the thimble, etc. The mold is not allowed to be welded, because welding will reduce the strength of the mold, or the subsequent customer needs to polish, sunburn, etc. There will be flaws.

7, all accessories need standard parts, if you must customize non-standard parts, you need to make spare parts for customers and explain.

8, must ensure that the final mold drawing and the mold physical time is consistent.